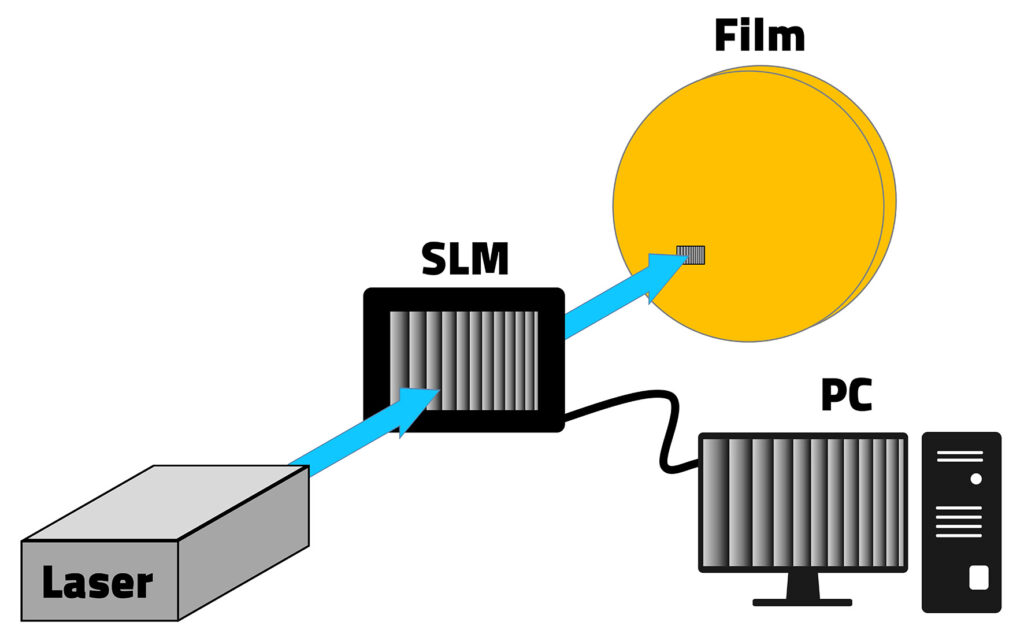

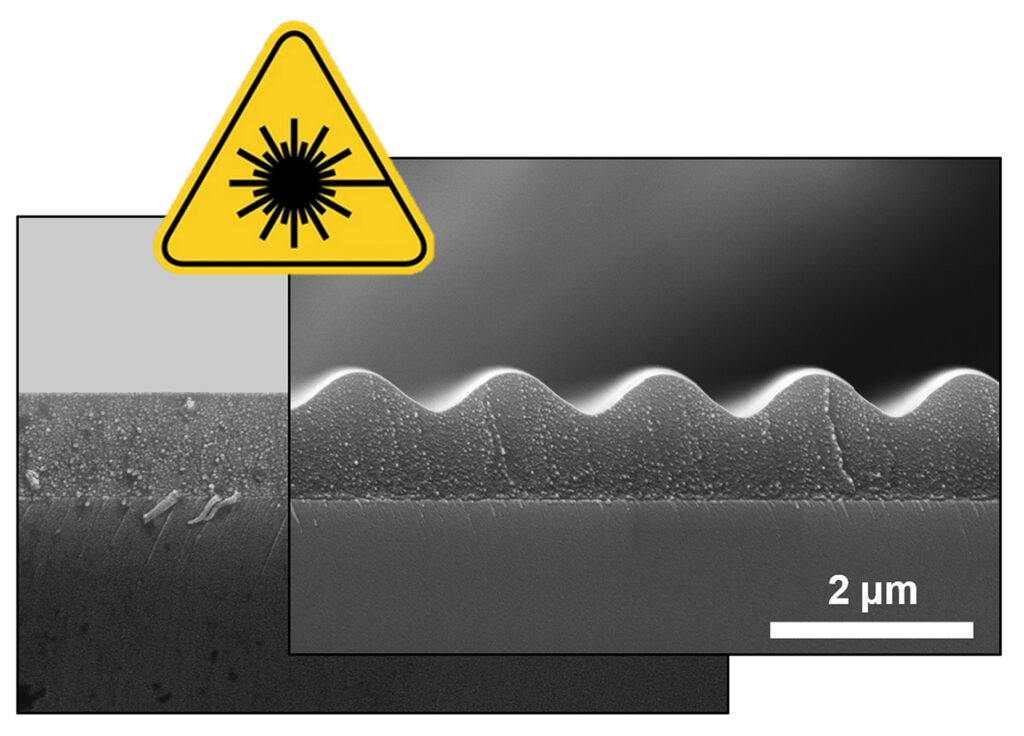

VectorScribe uses a commercially-available azopolymer film as a template for mastering surface microstructures. A user-defined pattern is projected onto the film with a blue laser and high-resolution spatial light modulator. VectorScribe’s unique polarization engineering (patent pending) drives surface structure growth in direct response to light, viewable in realtime, and with no chemical processing required.

- Maskless lithography

- One-step fabrication of surface micro structures

Patent

“Method and apparatus for laser lithographic fabrication of surface relief structures utilizing optical polarization projection and continuously moving photomechanical azopolymer films,” U.S. Patent No. 18/421,442

Capabilities

Current capabilities:

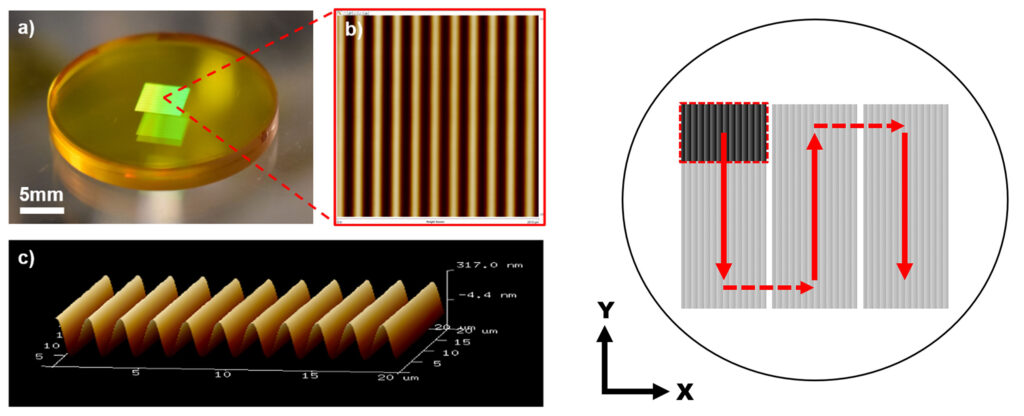

- Periodic structure features 700 nm -10 µm, including chirped structures.

- Surface modulations up to 1 µm

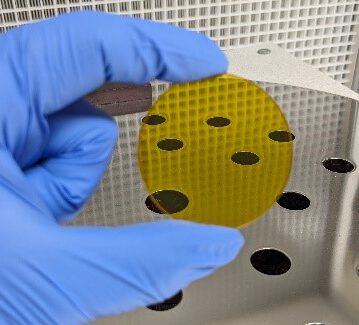

- Surface area up to 100 mm2

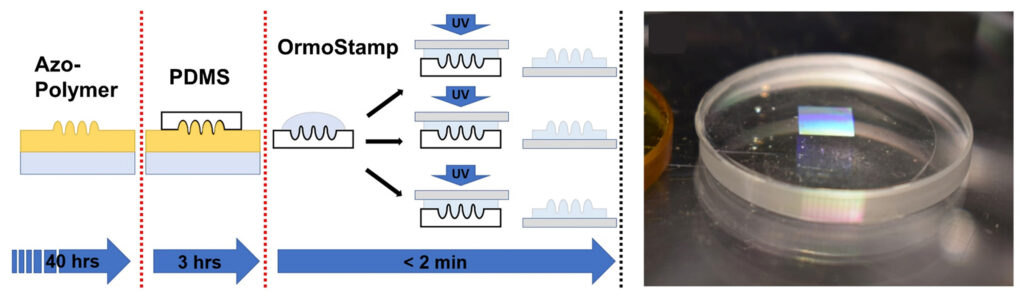

Microstructures can be provided on transparent PDMS and/or OrmoStamp. We continually expand these capabilities, so contact us for the most up-to-date information.

Flexible fabrication options

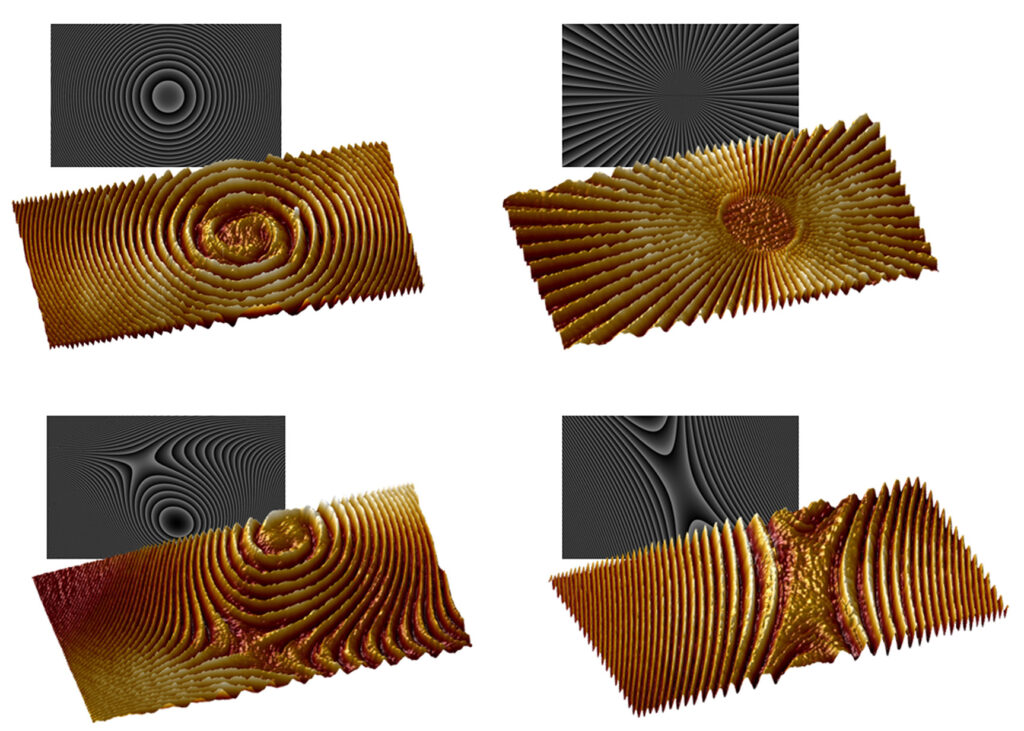

VectorScribe can fabricate structures on multiple configuration scales:

- Single exposures- microstructures of area 2.5 x 10-3 mm2 up to 0.1 mm2 can be fabricated in a single exposure

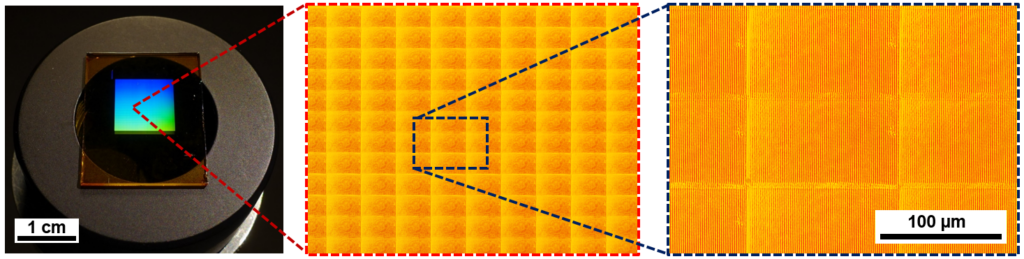

- Stitched exposures- microstructure arrays can be fabricated with precision XY stepping.

- Continuous exposures- Continuous XY translation enables boundary-free microstructure printing up to 100 mm2

Examples

- Single exposures

- Stitched exposures

- Continuous exposures